Wheat grain is normally of the oval shape and with heart-shaped cross section. Its grain size is measured in terms of length, width and thickness. Generally speaking, wheat grain size falls into the following range: 4mm~8mm long, 1.8mm~4mm wide and 1.6mm~3.6mm thick. In the flour milling industry, mesh size is normally adopted to represent the grain size.

Of course, the wheat grain size is in direct proportion to its water content. The same grain with higher water content will have relatively larger size and vice versa.

Comparatively speaking, wheat with larger grain size normally has lower bran ratio and higher endosperm content, leading to higher flour yield. Those grains with spherical shape have smaller surface area and thus much higher flour yield.

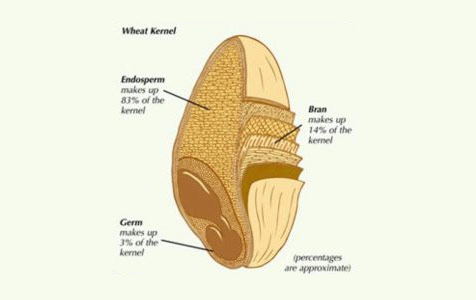

Wheat grain is composed of three major parts, namely, bran, endosperm and germ. Refer to image 1-1.

- Wheat bran

Wheat bran can be further divided into two parts: outer bran and inner bran (also called Aleurone layer).

The outer bran contains more crude fiber and tastes quite rough. As it’s hard to digest and absorb, we should try to avoid it from entering into the flour.

As for aleurone layer, it’s more nutritious and contains less crude fiber than the outer bran, therefore, when producing low grade flour, aleurone layer can be milled into flour to increase the flour yield. While producing high grade flour, it should be excluded from the flour due to its indigestible cellulose and higher ash content.

During flour milling, it’s inevitable for the bran to enter into flour even though the quantity could be quite small. These bran specks with same grain size as the flour have certain effect on the milling accuracy. For example, as compared to red wheat, white wheat with relatively light bran color has higher milling accuracy and higher flour yield. Wheat with thinner bran has larger endosperm percentage and as the adhesion between bran and endosperm is looser, it’s easier to extract the endosperm and thus has higher flour yield.

- Endosperm

Enveloped by bran, endosperm consists mainly of starch cells and forms the basic part of the flour. The larger the endosperm content, the higher the flour yield. Endosperm can be divided into two different structures based on wheat hardness. The starch granules inside the endosperm cells of hard wheat are filled with protein, thus the endosperm of hard wheat has more compact structure, darker color and transparent sections. For soft wheat endosperm, there are gaps among starch granules inside the cells and thus its structure is much loose and its sections are white and opaque.

In comparison with soft wheat, hard wheat has better milling quality, edible quality and nutritional quality in the following aspects:

※During flour milling process, large quantity of coarse-grained intermediate products can be obtained, which are suitable for making high grade flour.

※It’s much easier to extract the endosperm from the bran and with all other factors being same, its flour yield is much higher;

※The intermediate products have better fluidity, thus its screening is more efficient;

※The flour made from hard wheat is creamy yellow and contains more protein and with better quality. It’s suitable for making yeast-based food products like bread etc. and not fit for biscuits etc.

※As its endosperm hardness is relatively greater, it’s much harder to grind, which in turn causes the power consumption to be higher;

※With water absorption being high, the hard wheat contains higher water content when entering into the mill and thus requires longer water conditioning period.

- Germ

The germ, being the most vital part inside the wheat grain, plays an essential role in the water conditioning of the wheat grains. However, as the germ contains a lot of protein, fat and highly active enzymes, it will affect the flour color and, what’s worse, it makes the flour more perishable in storage and has bad effect in baking. Therefore, when making high grade flour, it’s better not to mill it into flour. But the germ itself has very high nutrition value and thus can be extracted from flour milling for other usage.